selective laser sintering (3D printing) (SLS)

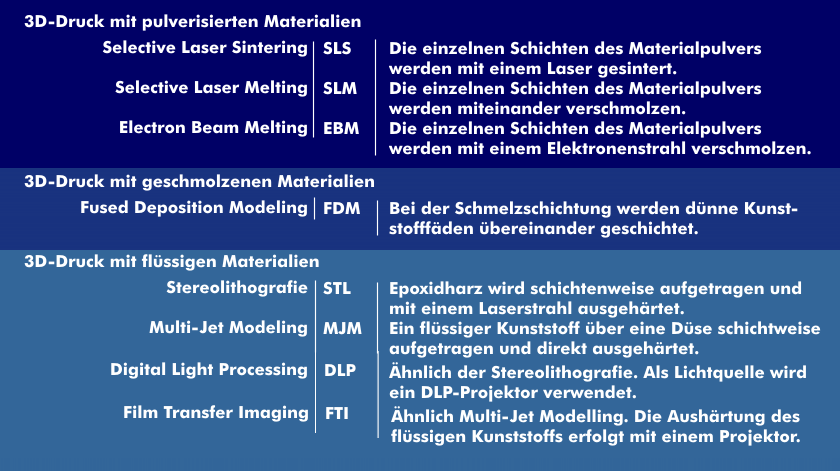

Selective Laser Sintering( SLS) is a metal 3D printing technique used for rapid prototyping. In selective laser sintering, the filament with the printing powder is applied in layers in thin layers and fused together in a sintering process.

In selective laser sintering, the filament is applied to the print object in layers and sintered with a laser beam from a powerful carbon dioxide laser. The print bed is then minimally lowered and the next filament layer is applied.

The filament is a plastic strand that contains a proportion of ceramic powder, metal powder or powder of other material. The layer thickness is between 1 µm and 200 µm. The individual layers are sintered or melted down after the metal powder has been applied. The resolution is very high and ranges from 1 µm to 200 µm.

The process of laser sintering is similar to the process of selective laser melting, although the printed pieces of the latter process have a higher density.

The production of 3D models using the SLS process is extremely time-consuming and can take several hours. This is due to the fact that after sintering, the print material must first cool before a new layer of print powder is printed. Therefore, laser sintering is primarily suitable for prototyping.