connector

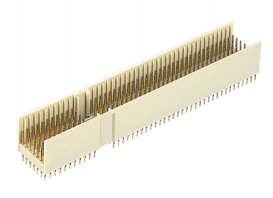

The connector is an electrical component used to connect electrical conductors to each other. With a connector, connections can be made with the corresponding counterpart and also disconnected. The difference between connectors and plugs is that connectors have more contacts, are plugged in indirectly, are usually attached to a replaceable printed circuit board, and the mating part is mounted on a subrack or motherboard.

Connectors consist of the contact carrier with the contact elements and, if necessary, a connector housing. The contact carrier is a plastic mold into which the contact elements are inserted and insulated from each other.

The connector housing

The housing protects the contact elements and provides contact protection. It can be made of plastic or metal and have a coding that makes it impossible to twist the connector. Metal housings also reduce interference radiation and improve EMC.

To secure the connector housing, it can have a mechanical latch, which is used to keep the connector in the contact state under heavy mechanical stress. A distinction is made between latching, rotary latching, spindle latching and safety latching. Shackle locking uses shackles that cannot be pushed into their final position until the two parts of the connector are fully mated. Other locking techniques use screws to secure the connector. Round connectors use rotary locking.

The contact levels of connectors

The contact level of a connector is sufficiently described by the number of contact elements and rows, by the contact spacing, the pitch, the contact principle and the contact material as well as the number of mating cycles. The pitch, which is defined in DIN 40801, is the distance between two adjacent grid lines for the connection of the contact elements. For printed circuits, the grid dimensionsaccording to the DIN grid are 2.54 mm, corresponding to 0.1", 1.27 mm (0.05"), 0.635 mm (0.025") and 0.254 mm (0.01"). Furthermore, there are metric dimensions of 2.5 mm, 2.0 mm, 1.25 mm, 1.0 mm and 0.4 mm.

As a contact principle, connectors use spring contact technology with elastic contact elements or blade contacts with rigid contact elements. The contact material depends on the required properties such as contact resistance, mating frequency and environmental influences to which the connectors are exposed. In most cases, the contacts are made of copper or copper alloys, but they can also be made of silver, gold, tin, nickel or palladium. If the connector is connected to a flexible printed circuit board, then it is an FPC connector; if it is connected to a ribbon cable, then it is an FFC connector.

The connection technology of the connectors

For PCB production, the connection technology of the connectors can be designed for THR technology or SMT technology. In addition to the design characteristics, the current rating and the associated heat dissipation play an important role for connectors. These specifications are defined in IEC 60512. Due to high data rates of several gigabits per second, which are transmitted via connectors, the crosstalk between the contacts and the RF capability play an essential role.