heat dissipation

Thermal stress on electronic components, packages, printed circuit boards, assemblies and devices increases their failure rate. The lower the temperature, the lower the failure rate. There are studies according to which the failure rate decreases by a factor of 5 to 10 when the operating temperature is halved. Therefore, heat dissipation plays a crucial role in failure safety.

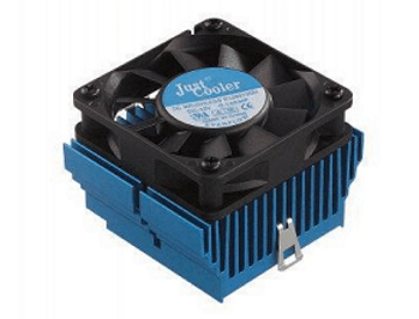

There are several methods to dissipate heat from components and boards. One of these is convection, which is the dissipation of the surface heat of the components into the air or into liquids. A distinction is made between natural and forced convection. In natural or passive convection, the air above the component heats up and rises. This creates a flow of air. In forced or active convection, a fan creates an airflow that dissipates heat from the component.

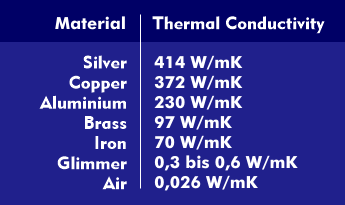

Another method of heat dissipation is conduction or heat conduction. In conduction, heat is transported in solid materials such as heat sinks, heat distribution plates, heat conduction pastes, heat conduction foils, heat conduction pads and phase change materials. The heat always flows from the points with higher temperatures to the lower temperatures. The thermal conductivity (`lambda`) of the material is decisive for heat dissipation. The thermal conductivity or the thermal conductivity coefficient is the reciprocal of the thermal resistance and is given in `W/(m*K)` and indicates the heat flow in watts (W) through a cube with an edge length of one meter (m) when the temperature difference on both sides of the cube is one kelvin (K). Copper and aluminum have the highest thermal conductivity values after diamond, which is why they are often used in heat sinks.

In techniques subject to high thermal loads, such as automotive engineering, silicone-based fillers are used for heat dissipation. These fillers are available as thermally conductive adhesives, pastes, gels or potting compounds.

Heat radiation is another principle of heat dissipation. According to this principle, warm bodies radiate heat rays, cold bodies absorb the heat rays. The heat rays are comparable in their properties to visible light, they can be emitted, reflected and absorbed. The surface properties of materials are important for heat emission and absorption. Matt black surfaces have particularly high emission and absorption properties, which is why heat sinks are painted or oxidized accordingly.