tight buffered cable

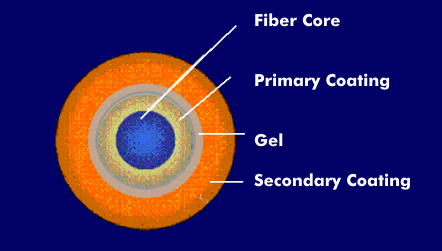

The designation solid conductor or fixed conductor characterizes the constructive structure of an optical waveguide. This is characterized by a small diameter because the two coatings, the primary and the secondary coating, are firmly connected to each other. The optical waveguide is therefore directly surrounded by two protective coatings.

During the production of the solid core, the secondary coating is applied in an extrusion process in such a way that there is a firm bond with the primary coating. According to DIN, the diameter is 0.9 +0.1 mm. However, newer FO connectors require a secondary coating of 600 µm.

Since all longitudinal and transverse forces acting on the sheath act directly on the fiber in the solid core, the primary coating and the secondary coating must be optimally matched to each other. Various forces act on the fiber via the secondary coating. These include transverse forces, tensile forces and temperature-dependent forces.

Since the secondary coating is applied at a temperature of approx. 2000 °C and a bond with the primary coating occurs at this temperature, compression forces also act on the fiber because the plastic shrinks during the cooling phase. According to the expansion coefficients of the different materials, the fiber is subjected to all temperature changes.

When the cable is laid, for example when it is pulled into cable ducts or shafts, the tensile forces act directly on the fiber via the secondary coating.