short wave (SW)

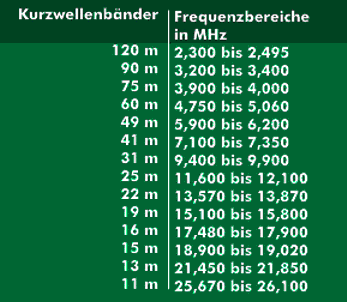

The shortwave (SW) frequency range is between 3 MHz and 30 MHz, and its wavelengths between 10 m and 100 m are subdivided into various shortwave bands. These shortwave bands are designated as meter bands and are assigned to the corresponding frequency bands.

Shortwave is also a broadcasting term for radio in the frequency range between 2.3 MHz and 26.1 MHz. For reasons of frequency economy, shortwave broadcasting uses extremely narrowband voice transmission with single-sideband modulation. The typical modulation code is H3F.

Since the transmission bandwidths in shortwave transmission have been increasingly restricted and are as low as 5 kHz, the transmission quality can be described as poor. Shortwave is therefore mainly characterized by amateur radio operators.

In terms of propagation, shortwaves are space waves that are between 10 m and 100 m long and are radiated linearly from the antenna into space. Short waves are reflected at the ionosphere and can even be earth-orbiting.

Since the transmission quality of shortwave is extremely poor, a digital alternative has been developed in the form of DRM radio, with which transmission rates of up to 24 kbit/s can be realized in the available channel widths and which is characterized by high transmission quality.