thermal transfer printer

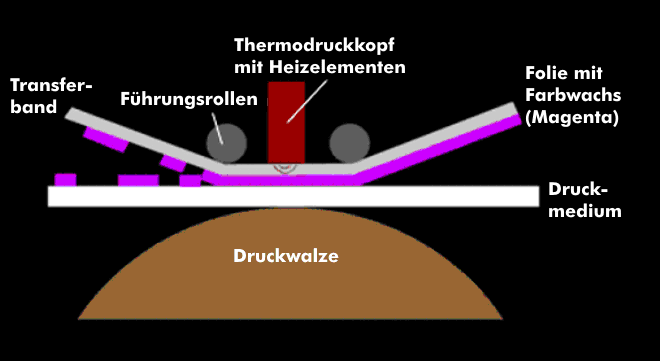

The thermal transfer printer transfers wax inks to paper or other substrate by heating. Heating takes place via thermocouples located on a heating bar.

The wax inks are applied to colored foils or ribbons. They are heated at the points, the wax liquefies and is transferred to the carrier medium. To produce color tones, the individual colors are printed one after the other using halftone technology and dithering. This technique is necessary because thermal transfer printers, unlike dye sublimation prin ters, cannot print halftones.

Like other color printers, thermal transfer printers work according to the CMY or CMYK color model. When printing, the ribbon with the wax colors is unwound around each set of color foils.

Thermal transfer printers can print on various materials, such as paper, foil, textiles, metals, etc. and are used as label printers, among others. The color resolution is over 300 dpi, but the color quality is lower than that of dye-sublimation printers. Thermal transfer printing has advantages for full-surface representations such as those used in presentations.