electrowetting

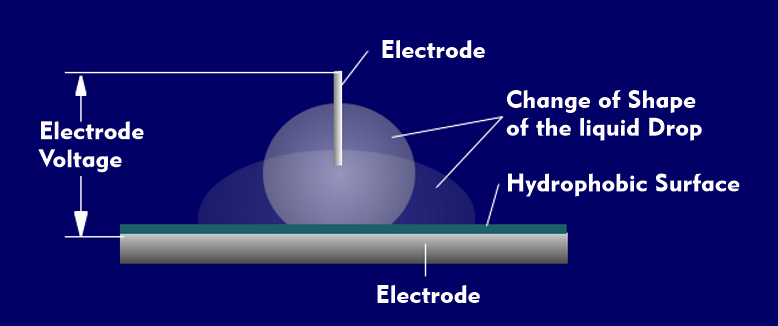

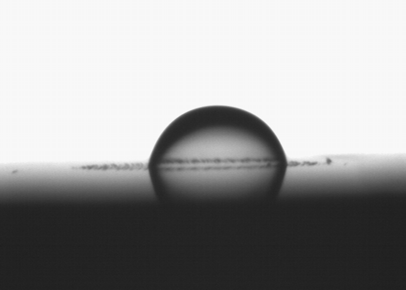

Electrowetting means electro-wetting. Electrowetting uses a microfluidic phenomenon to change the shape of tiny liquid beads. Electrowetting deforms the surface tension of liquid beads by applying an electric field. If the electric field on the liquid bead is reduced, then the surface tension is also reduced and the liquid bead becomes wider.

The deformation of the liquid bead can be used functionally like an optical switch or an optical lens. Therefore, the electrowetting technique can be used in electro-optical components, microfluidic systems and displays.

As for the function of an optical switch, depending on the applied voltage, the deformation of the liquid bead located in a microcell can be so large that the microcell transmits or blocks light passing through it. This application is realized in the Electrowetting Light Valve( ELV), a microcell that can be used in displays. In this process, the droplets are spatially confined and colored. By applying a control voltage, such a liquid cell can be switched to permeable or colored. A corresponding electrowetting display can be formed from an array of controllable liquid cells.

Electrowetting in optical lenses

Another area of application is optical lenses in cell phone cameras. These have neither a focusing device nor a possibility for zooming. Such camera lenses consist only of two liquids with different refractive indices that cannot be mixed, like water and oil. Electrowetting can be used to continuously change the shape of the liquids and thus the liquid lens and its focal length. Such liquid lenses are 3 mm or less in diameter and can be focused in a few milliseconds, from close-up to infinity. They are used in cell phones, smartphones and tablets, among other things.

Another area of application is the precise positioning of tiny electronic components on a printed circuit board, as developed by the Fraunhofer Institute for Reliability and Microintegration. In this technique, the tiny components are transported in the liquid bead on a water-repellent surface. The surface is treated with nanoparticles, making it hydrophobic. The water droplet is moved by electric fields generated in the circuit board. To generate the electric field, there is a fine electrode structure in the printed circuit board that ensures µ-accurate positioning of the electric field and thus of the water droplet. If the water drop is positioned with the tiny component, then the component assumes the exact position after the water drop evaporates.