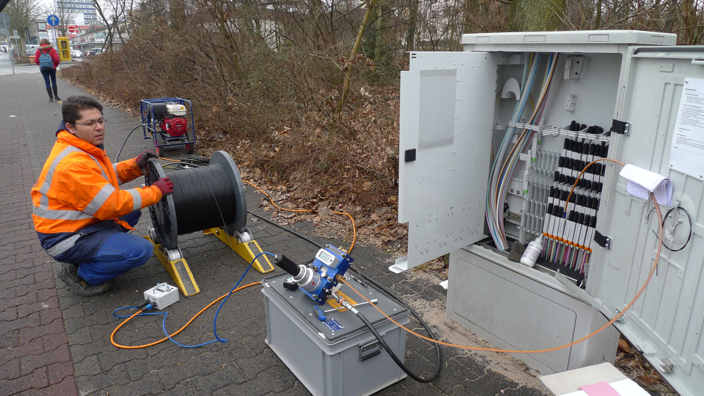

blow in fiber

Blow-in is a special process for the subsequent laying of fiber optic cables. For this purpose, empty pipes or speed pipes are laid during cable laying, into which fiber optic cables can be blown with compressed air.

The optical fibers are blown into microducts, which are laid in the empty conduits or directly in the ground. These microducts are also known as speed pipes and have a diameter of 3 mm to around 20 mm. They have a slippery inner coating, as do the LwL conductors, which have a special coating that allows them to slide in the empty condu it, overcoming even tight bends with small bending radii.

Due to the high sliding ability, there is only little friction, which makes high laying lengths of several kilometers possible. To blow in the fibers, a fiber-optic blowing device is required, with which compressed air is forced through the speed pipe. The glass fiber lies on the air cushion and there is hardly any friction on the inner wall of the Speedpipe.

A major advantage of the blow-in technique is that older glass fibers that no longer meet the requirements can be blown out using compressed air and replaced by new ones.