angle polished convex (fiber optics) (APC)

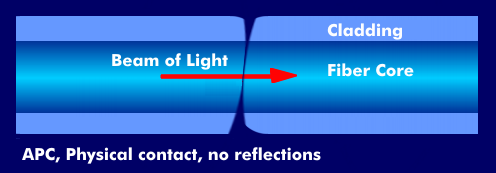

In order to keep the light reflections at the joint between two optical waveguides as low as possible, the end faces are treated differently.

In general, there is the convex shape of the end face with direct contact between both optical waveguides, Physical Contact( PC), and the obliquely ground end face, Angle Polished Convex( APC). In the APC grind, the front surface coupling is an oblique grind coupling with an additional bale-shaped feature. It is an aspherical shape, which also stands for Aspherical Physical Contact.

The bevel of the end faces is oblique to the longitudinal connector axis and has an angle of inclination of 8°, more rarely 9°. This is to avoid the reflection losses from end face coupling, where the beams are reflected into the cladding glass. Connectors with APC coupling are low attenuation, reflection-free and have a high optical return loss, High Return Loss( HRL), of over 60 dB. Their insertion loss is less than 0.3 dB. However, they are difficult to polish. The polish is extremely fine, as with Ultra Physical Contact( UPC).

The oblique ground coupling is used in a wide variety of connector types. This is the case with the LC connector, which is then referred to as the LC-APC connector. The same is true for the SC connector, which is called SC-APC connector, for the ST connector, ST-APC, E-2000 connector, E2000-APC, DIN connector, DIN-APC, and FC connector, FC-APC.